We are SPIRALWELD™

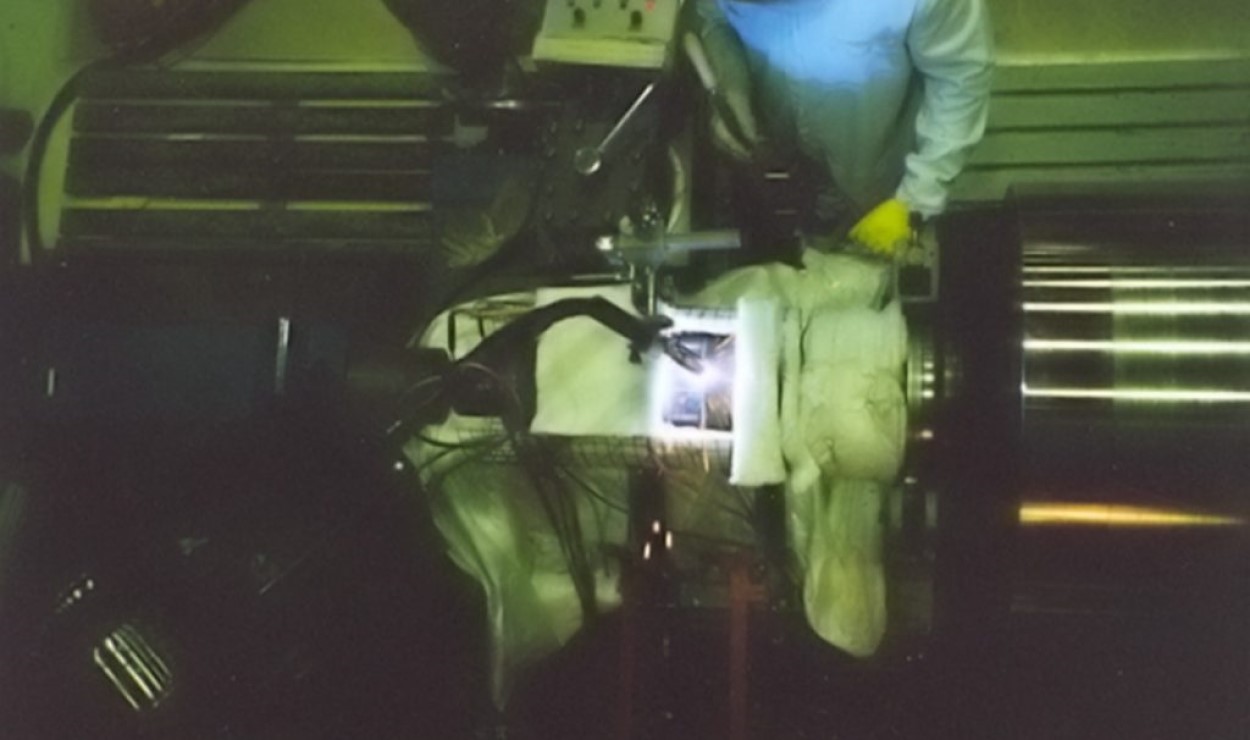

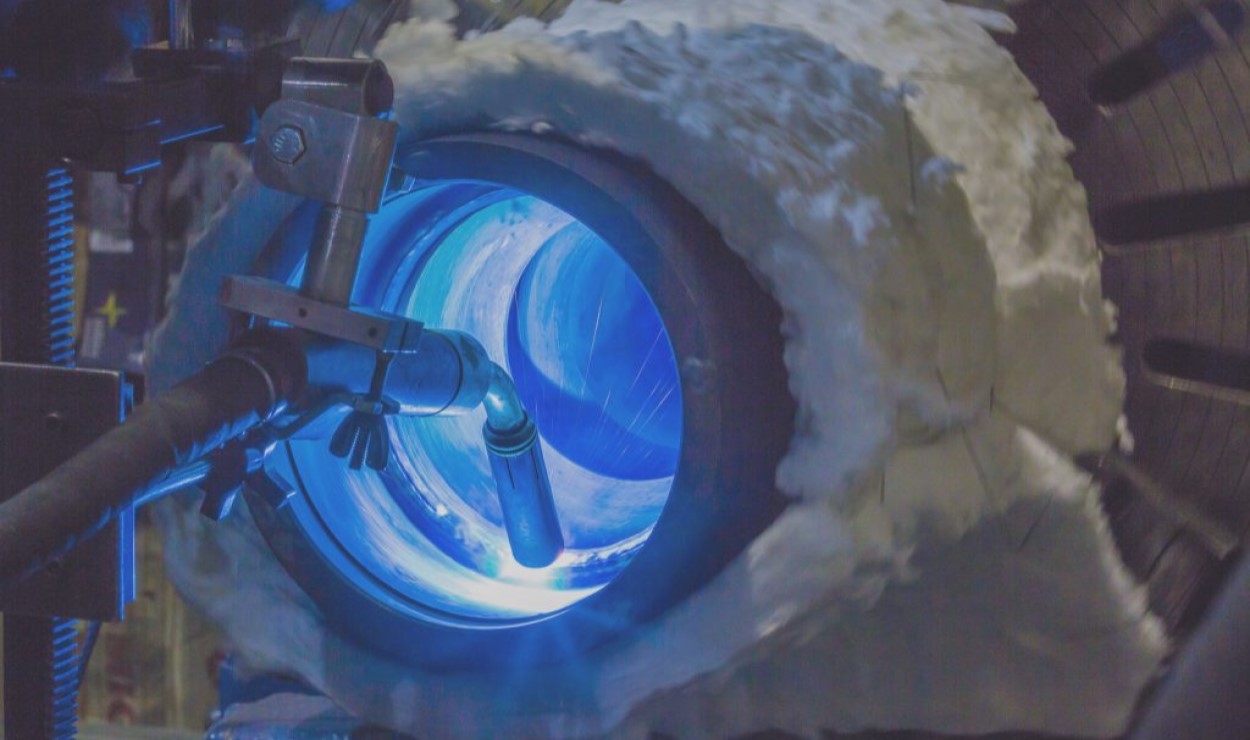

SpiralWeld™ specialises in developing innovative solutions using our proven technology to solve your most critical component repair challenges.

For over 30 years we have provided mission critical ReManufacture and ReManufacture+ engineered solutions. We tune our business to the commercial demands placed on yours – providing the right result, on time, at the right cost, all backed by our comprehensive performance warranty. We often get difficult requests that our competitors either cannot, or will not, support. We have a ‘can do’ professional engineering approach and our team thrives on the opportunity to work on new, challenging projects

We recently held a webinar, to discuss the typical failure modes experienced by power generation control valves and ancillary equipment. For those unable to attend, we have made the presentation available for download. Click the button below to access the presentation and look out for updates about future webinars.

The Benefits of SpiralWeld™ ReManufacture and ReManufacture+ Solutions

Reduce downtime by up to:

Minimise maintenance costs by up to:

Improve component life by up to:

SpiralWeld™ and the Circular Economy

Our services present an opportunity for our customers to make an environmentally friendly choice and take steps towards a circular economy. For more information on how we support the values of the circular economy, click here.

What Our Customers Have to Say

“Thank you for an excellent job. The 10” stem has been delivered, inspected and receipted. With our two major outages next year I would like to set up a service contract with you.”:

“I have inspected the plug assembly and all looks good…Thanks for the great service – as usual”

“Excellent value, excellent service”

“Received a quick response quote. Job carried out as per order”

“SpiralWeld are very easy to work with. I received a fast response, and they completed the job quickly with no issues”

“I have inspected the plug assembly and all looks good…Thanks for the great service – as usual”

“It’s a pleasure working with Spiral Weld”

“I will definitely be using Spiral Weld again”

“Overall I am very pleased with Spiral Weld”

Spiral Weld did exactly what they said they were going to do; they were fast, friendly and cost effective. Overall an A1 service.”

“Quality of the work was good, you did the job as I asked”

” Many thanks for all the hard work over the last year – really appreciate the dedication to constant development and innovation to improve the reliability of the component at site – life would be a lot easier if more companies had the positive attitude that you have your attitude and passion towards the work is seen with so few people let alone companies these days and it is great to work with you”