The Challenge

Energy from Waste (EfW) plants handle bulk waste and require it to be processed (shredded) before it can be effectively blended with other waste. This waste is then loaded into the feed hopper and onto the combustion grate for incineration.

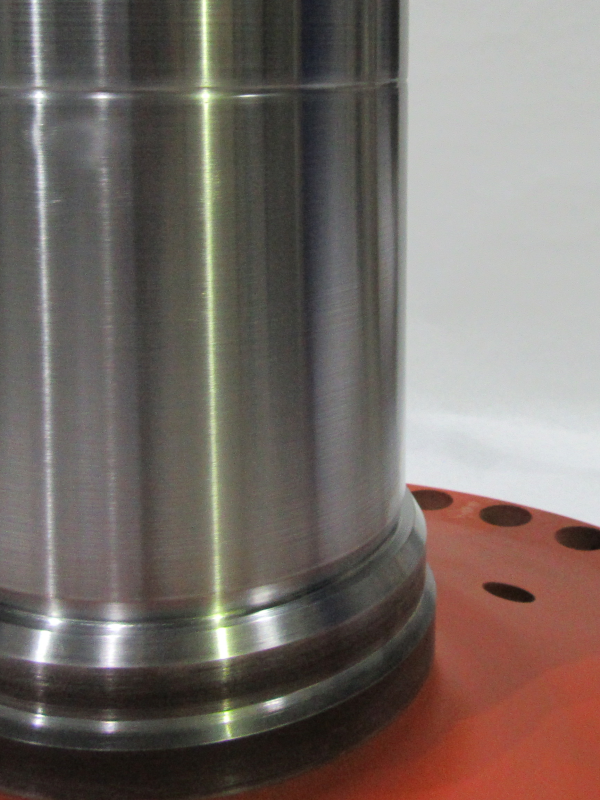

SpiralWeld Ltd has successfully ReManufactured an EfW shredder transition shaft that had suffered journal damage following axial fretting of the radial and thrust bearings. Replacement of a shaft of this size for a relatively minor dimensional issue would be excessive, especially given the lead time of a new forging. ReManufacture of this shaft, to return the journal to dimension, is standard work for SpiralWeld Ltd. However, even a shallow weld recovery activity can offer up specific challenges.

Solving The Problem

Material wet analysis indicated this shaft was made from a medium carbon steel, required to give the shaft strength but at a low material cost. The level of carbon detected demanded careful overlay selection, weld pre-heat, weld interpass temperature control and post weld heat treatment. This is needed to ensure correct hardness transition through the weld heat affected zone.

Welding of medium to high carbon steel without consideration of the metallurgy and weld parameters can result in an unsatisfactory hardness gradient. This can lead to crack propagation at the heat affected zone, where the hardness can differ by up to 20HRC if welding is not carefully controlled.

A Successful Outcome

SpiralWeld Ltd successfully completed the journal ReManufacture of this shaft, developing a technically robust recovery plan. After pre-machining to an adequate depth to promote optimum weld placement the journal area was weld overlaid, ensuring weld parameters were controlled throughout. The welded area was subjected to a suitable post weld heat treatment to stress relieve the overlay. Finally, finish machining was completed, which required both p6 & h6 tolerances at different axial locations to facilitate correct thrust and radial bearing interference fit.

What may appear a straightforward activity may contain unique challenges such as this. Thankfully, SpiralWeld has a wealth of experience in shaft recovery for power generation and marine customers and is more than capable of supporting our customers to avoid lengthy cycle times.

If you need further information on our services, please do not hesitate to contact us.