Summary

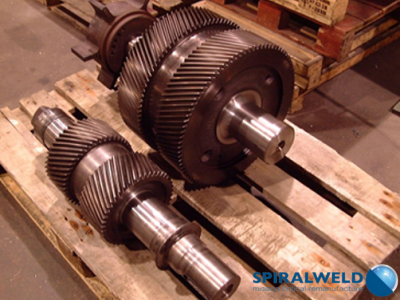

SpiralWeld™ can ReManufacture Gearshaft materials without the need to remove the shaft from the gear. Gear to shaft interference fits are highly toleranced and can cause more damage to the shaft or gear bore surfaces as the shaft is removed.

Keyed gear fits can be recovered (following removal of the gear if necessary) by SpiralWeld™ methods developed over the last 30 years.

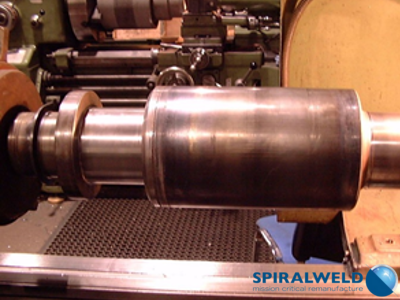

Pinion bearing journals are ReManufactured without affecting the surface hardness of the gear-teeth because of the low heat input ≤ 1Kj/mm2 during the SpiralWeld™ process.

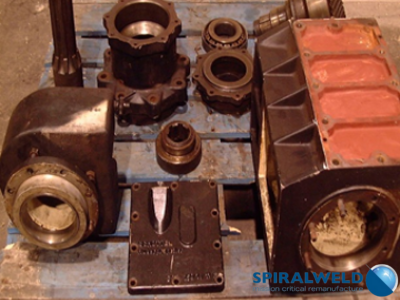

Even relatively small gear drive components can be SpiralWeld™ ReManufactured quickly and cost effectively. Smaller gearbox components and relatively Small gear bores present no ReManufacture problems for our experienced machinists.

Gear wheel interference fits, radial and thrust bearing journals can be cost effectively reinstated with high structural integrity by SpiralWeld™ ReManufacture and ReManufacture+ processes to introduce beneficial surface properties that will not crack or delaminate.

If you need further information on our services, please do not hesitate to contact us.