Introduction

What is Microbiological Corrosion?

Microbiologically influenced corrosion (MIC), also known as biological corrosion and microbial corrosion, is metal deterioration caused by metabolic activity of micro-organisms. Corrosion can be caused by organisms called Chemoautotrophs, which derive energy for their life functions from inorganic chemicals. They feed on chemicals that are good electron donors, such as hydrogen sulphide, sulphur, or iron. Additionally, aerobic bacteria such as Acidithiobacillus thiooxidans can cause significant corrosion as it serves as a factor in biogenic sulphide corrosion as it uses sulphur as a primary energy source.

There is a wide range of bacteria in water known to provoke MIC in such materials as:

- Stainless steel

- Carbon steel

- Copper alloys

- Aluminium alloys

Such bacteria can be both aerobic and anaerobic. For instance, sulphate reducing bacteria (SRB) is considered to be accountable for many instances of hastened corrosion to offshore steel as well as ships, although it only exists in stagnant, deep water. In surface sea water, other specific types of micro-organisms are responsible for catalysing the reduction of oxygen in the biofilm, leading to the formation of hydrogen peroxide. These are typically related to accelerated corrosion pitting attacks in stainless steel.

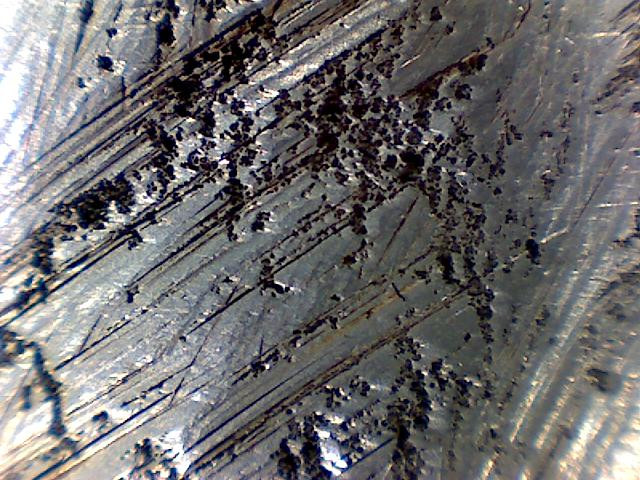

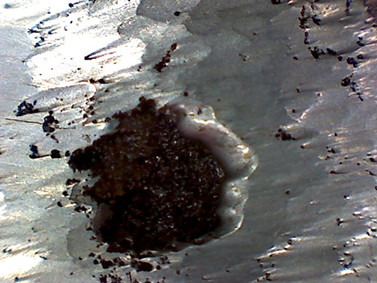

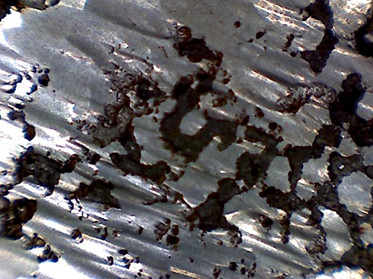

The areas of MIC infestation appear as visible pitting in the surface of components however these areas can open up below the surface and be extensively deeper than they appear. If left untreated, MIC can cause stress raisers due to the random and rough crevasses created and increases the likelihood that components can begin to crack.

Investigation

At SpiralWeld™ we see the results of this problem occur often and have developed a structured set of procedures to combat and eradicate the damage caused by these microorganisms. We microscopically examine the components to identify and map the MIC corrosion. Images above show the microbes at x 250 magnification.

Solution

Once the extent of the infestation is mapped, we carefully excavate the MIC either by hand grinding or machining to remove all imperfections caused whilst minimising material removal thus minimising weld recovery required. In some cases, there is risk the MIC has fully penetrated thin walled areas as seen on impeller vanes.

Excavation success is validated by reinspection microscopically at X250 magnification to ensure that all of the infestation has been cleared out.

Once all MIC removal has been confirmed next stage is the application of careful TIG or MIG weld to SpiralWeld™ EN ISO 15614 part 7 qualified procedures to recover the excavated/machined areas.

Depending on the component and remaining scope, the weld recovered areas are returned to drawing dimensions and all recovered areas are inspected with the appropriate non-destructive testing techniques, both internally and by a 3rd party (when required) to confirm the integrity of the MIC removal.