The Challenge

Mixer shafts, which drive the mixer blades in a cement mixer, are subject to severe wear and tear. Their degeneration is accelerated by dust and grit penetrating the bearing journals at each end.

Our client, a leading company in the aggregates sector, was seeing significant wear in mixer shafts within 18 months of installation. As a result, it sought a sustainable solution that would prolong the shafts’ operational life, reducing downtime and the need for costly replacements.

The Solution

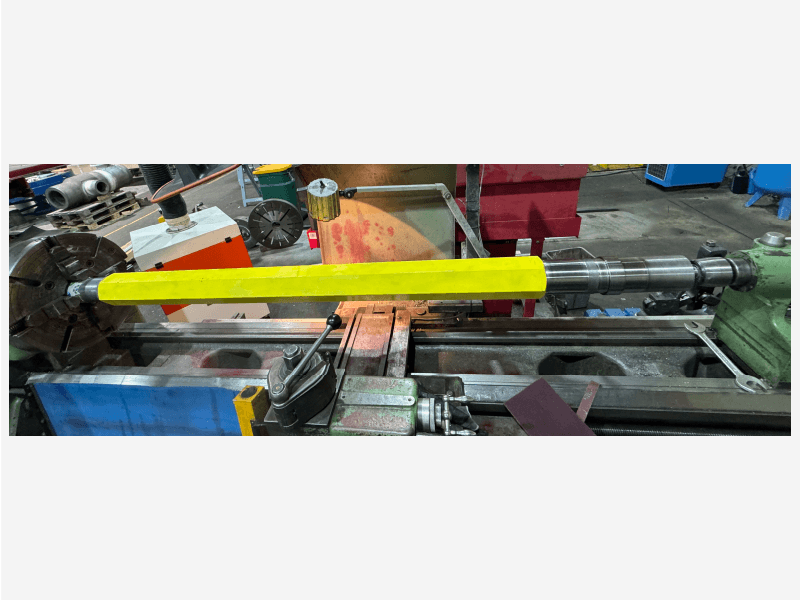

After inspecting a mixer shaft at one of the client’s sites, SpiralWeld’s engineers confirmed the parent material and that the bearing journal could be overlayed to bring it back to the designed dimensions.

The client then planned a maintenance stop in which the recovered shaft would be fitted.

SWL cleaned the journals, weld overlayed, and finish-machined to the prescribed dimensions, including including re-cutting the thread for the lock nuts.

The process included designing and manufacturing a sleeve to increase the mixer shaft diameter, which was significantly smaller than the internal diameter of the coupling.

During the fitting of the shaft, to minimise downtime, we were able to support the client with immediate modifications as they arose, for example, cutting a new key, adjusting the coupling, and recovering, sourcing and adjusting nuts and tab washers to secure.

The Results

The new mixer shaft was installed successfully and is running smoothly. We are working with the client to improve the sealing around the bearing journals to minimise the ingress of dust and particulate.

Our work is expected to result in significant cost savings compared to the cost of a new shaft, as well as a reduced carbon footprint.