The Challenge

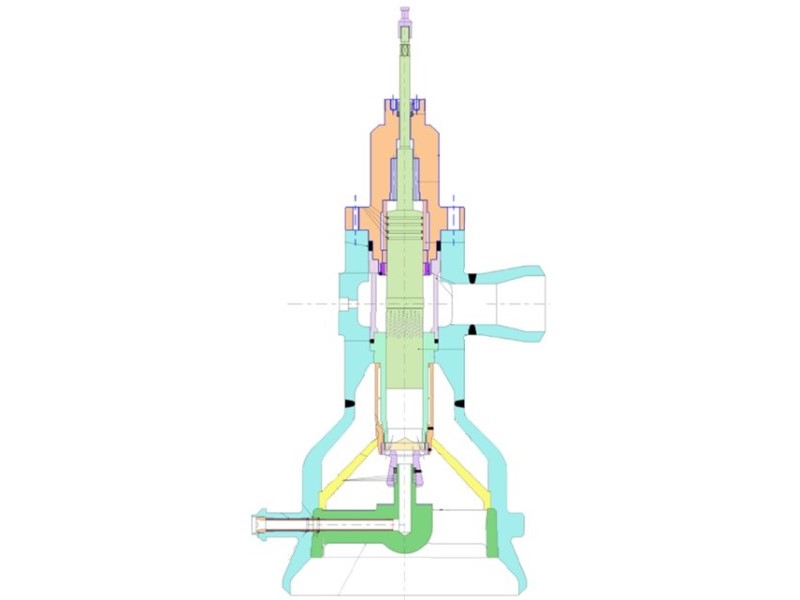

SpiralWeld Ltd were urgently approached by an EfW power station that had suffered an HP turbine bypass valve failure. This valve is critical to station operation and no spares were on stock to carry out a repair in the very short maintenance window.

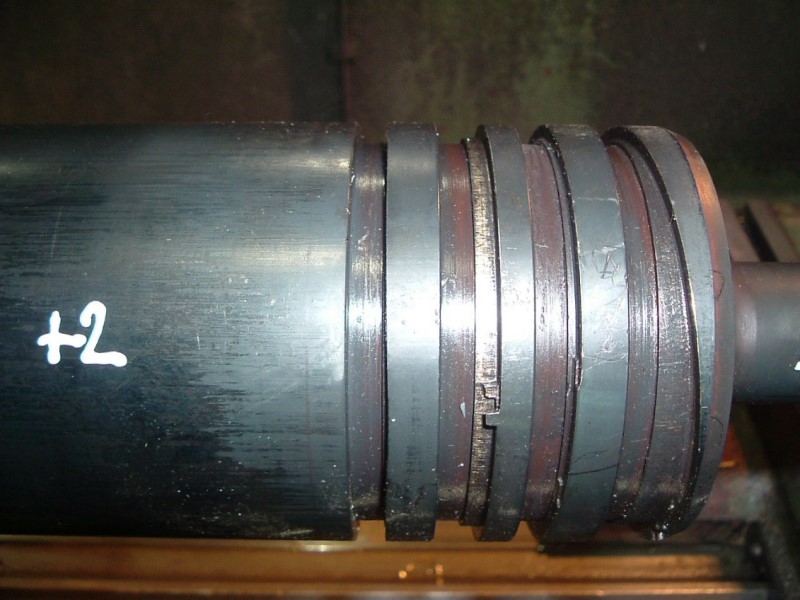

The valve was designed for vertical operation; however, this particular installation was horizontal and resulted in the valve stem piston rings dragging on the piston bore. This led to excessive wear of the piston ring grooves, resulting in loss of operating performance and eventual failure of the piston rings. The stem of the piston had also suffered wear that required recovery before a return to service.

Solving the Problem

SpiralWeld Ltd offered a ReManufacture+ solution to recover the piston ring groove area with a tougher material for improved wear resistance.

The materials of original manufacture were an exotic DIN specification high temperature creep resistant martensitic stainless steel, normally requiring Post Weld Heat Treatment (PWHT). As the customer required urgent return to service, we elected to SpiralWeld™ ReManufacture+ this component using an EN ISO 15614 qualified “Cold Weld Procedure” that required no PWHT.

SpiralWeld™ ReManufacture+ of this complex component was completed in three days and the station were able to resume normal commercial operations.

SpiralWeld has subsequently provided ReManufacture+ solutions to many of these assemblies as part of the station’s routine maintenance programme, providing upgrades to enhance performance as well as supporting general overhaul activities of these assemblies. These include boring out and replacing guide & piston bushes, as well as providing new perforated inserts to help maintain good steam flow.

In addition, heavy erosion has been observed on the attemperating lance guide which sits in the steam path. If left unchecked, this would result in break through to the attemperating flow path. This area was overlayed with erosion resistant material to restore the lance guide and reduce, if not halt, future erosion.

A Successful Outcome

Subsequent follow up inspections have proved that the upgraded overlays are performing better than the original materials; with the result that the station have installed significant SpiralWeld™ ReManufacture+ upgrades to all the mating components in this expensive attemperating HP steam bypass valve.

This customer operates three of these valves in parallel to control steam flow to the generator drive turbine. SpiralWeld™ ReManufacture+ has allowed this EfW operator to run the three production lines between outage intervals without this valve breaking down, validating the mean time between failure value statement of the SpiralWeld™ ReManufacture benefit.

If you need further information on our services, please do not hesitate to contact us.