Introduction

Most modern large and medium pleasure, passenger and freight vessels use stabiliser fins to correct Roll and yaw, in constant operation the stabiliser fin stocks wear at the bearing journals or at the fin assembly taper.

The materials of construction can be high tensile alloy steel, Martensitic and Precipitation Hardening Stainless and Copper Alloyed special steels for strength and to prevent corrosion in a seawater environment.

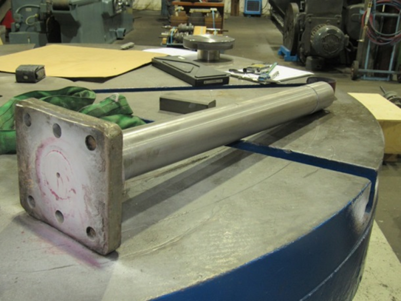

We received a damaged Rudder Stock for ReManufacture from a client who operates a fleet of sightseeing boats on the River Thames. The Rudder Stock had been subject to erosion and wear damage, and it was no longer fit for service.

Investigation

The Rudder Stock was subjected to vigorous inspection, including an in-house XRF analysis to identify its material composition. We firstly identified and investigated any observable damage, which in this case appeared to be the common wear and corrosion usually found on rudder stocks. To identify any less obvious damage a Non-Destructive Test (NDT) was carried out. The NDT showed major cracking where the shaft was welded on to the palm plate. On further inspection the root cause was due to previous poor welding repairs, which if left un-repaired would have failed in service.

Solution

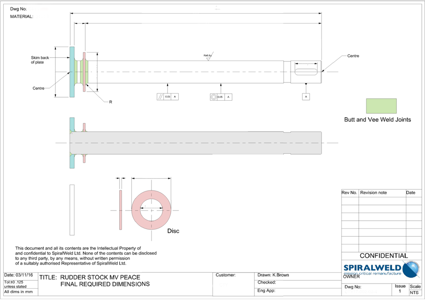

The rudder stock was reverse engineered using our in-house Faro arm (3D-coordinating) and XRF-analyser. This information was then used to make a CAD drawing of the rudder stock.

The SpiralWeld™ solution was to remove the palm plate from the shaft and manufacture a new stock from superior materials, making the rudder stock less susceptible to erosion and wear damage.

SpiralWeld™ technology offers our Marine clients a more economically viable solution to buying new. This includes components such as Rudder Stocks, Prop Shafts, Stabilizer Stocks, and Tail Shaft Liners (deep sea seals). If you are looking for a more cost-effective solution in the short and long term then please do not hesitate to contact us.