The Challenge

A Nuclear Power Station client contacted us to see if we could offer a solution for a highly stressed valve seat in the boiler HP Bypass System. Their usual supplier had closed so were in need for an alternative source, additionally they were seeking improved service life from the component. SpiralWeld Ltd has years of experience in cost effective alternative manufacturing support for new components as well as offering upgrades to enhance service life.

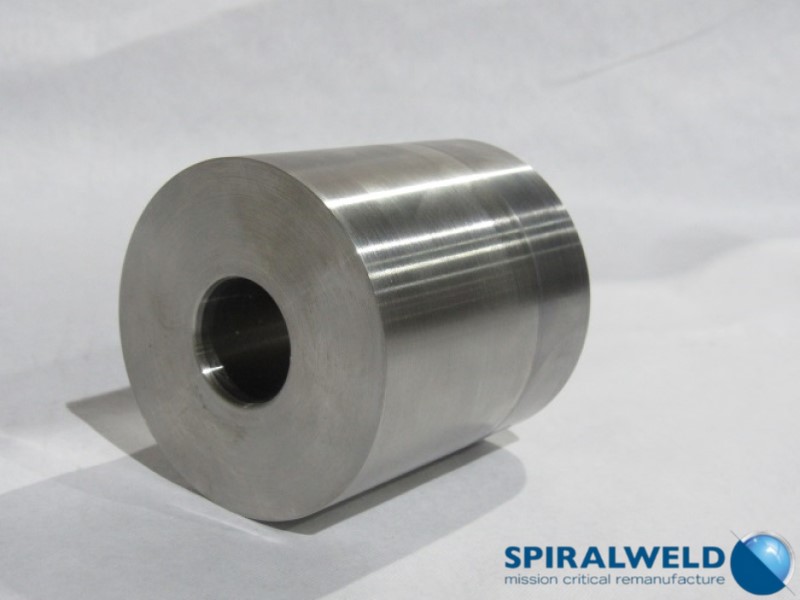

Following a full assessment and reverse enigneering of a failed component we determine all dimensions and orignal materials. Consequently, it was shown that the original design had used Stellite® hard facing material. This material is prone to cracking and delamination fron the substrate in service, (see our IP Intercept case study for a good example of this problem).

Solving the Problem

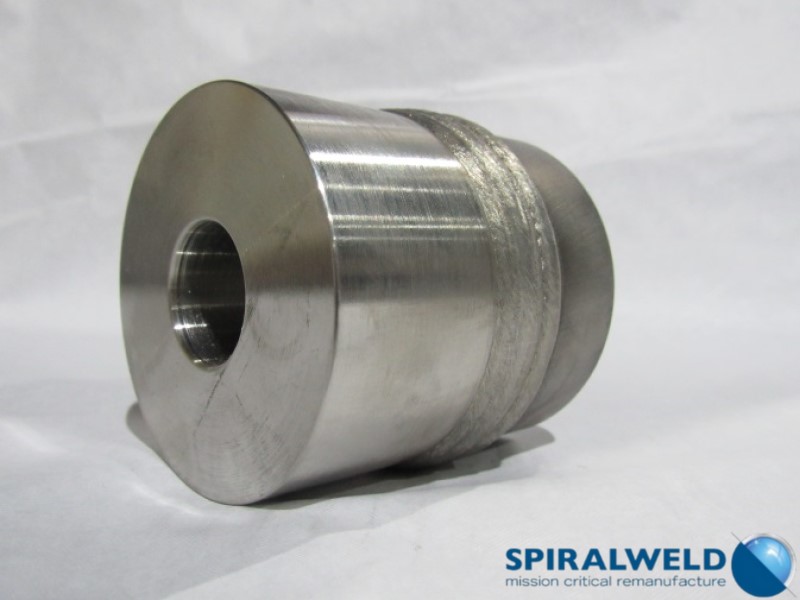

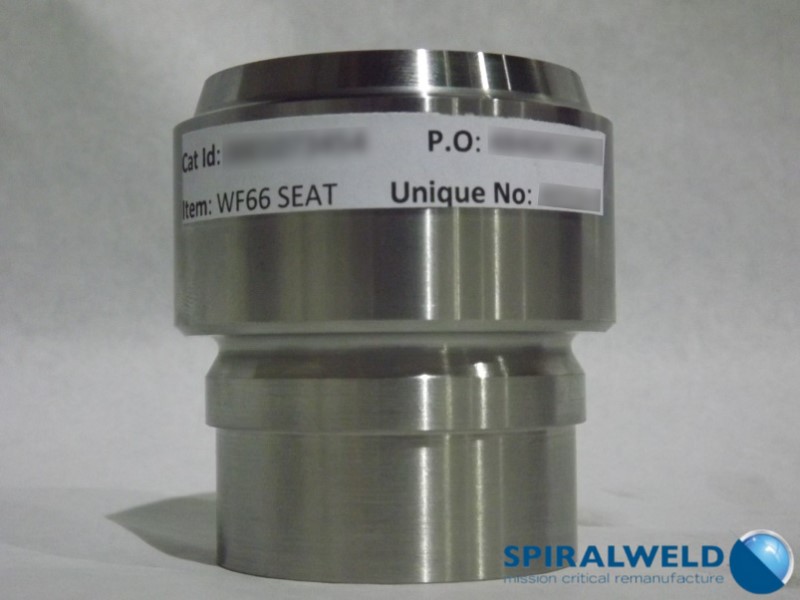

We were able to propose a Manufacturing+ solution for this component, providing a new component with use of an advanced Cobalt alloy to form the seat, fully welded to the parent material. The proposal included qualification of the weld procedure (WPQR) for the advanced Cobalt alloy in accordance with standards EN ISO 14732: 2013. This includes laboratory micrographic and mechanical tests, dye penetrant NDT, macro examination, macro photograph and hardness survey across the weld and Heat Affected Zone (HAZ).

An overview of the steps taken to provide the Manufacture+ component:

- XRF analysis of an original component to determine materials used.

- Co-ordinate measuring machine to determine all dimensions.

- Engineering and Technical review to determine the required course of action.

- Determine then Qualify the WPQR needed.

- SpiralWeld ReManufacture plus process to required technical and quality standards

- Compile full documentation and certificate of confirmance for customer records

A Successful Outcome

We were able to support our customer with thier mission critical component supply as well as meet the requirement of improved service life on the OEM design. The cycle time for supply was a matter of weeks, rather than months compared to previous sources and at a cost ~60% of orignal parts.

If you need further information on our services, please do not hesitate to contact us.