Aggregates & Construction Materials

SpiralWeld repairs and remanufactures vital components used in the aggregates industry, creating parts that are more hard-wearing and long-lasting than those available from the OEM.

Components include:

Components include:

- Mixer blades – see case study

- Mixer shafts – see case study

- Pouring chutes

- Hopper hinges

- Gearbox Spider Joints

Better able to withstand the demands of daily operations, our solutions reduce the need for frequent downtime to repair and replace.

Additional benefits include

- Significantly extended lifespan for parts

- Less waste

- A more sustainable operation with a reduced carbon footprint

- Cost and efficiency savings

Our Service for the Aggregates Sector

Remanufacture+

We take the OEM solution and improve it! We re-engineer and remanufacture the part using a superior material with properties to suit the service conditions.

A detailed quality plan, certification and warranty can be provided for each project.

Aggregates case study – Mixer Blade

Our client, a leading company in the aggregates sector, found that the blades available from the OEM were wearing in less than a month. Redesigning the blade, utilising a single plate that no longer relies on brittle hard facing, our solution is significantly outperforming its predecessor.

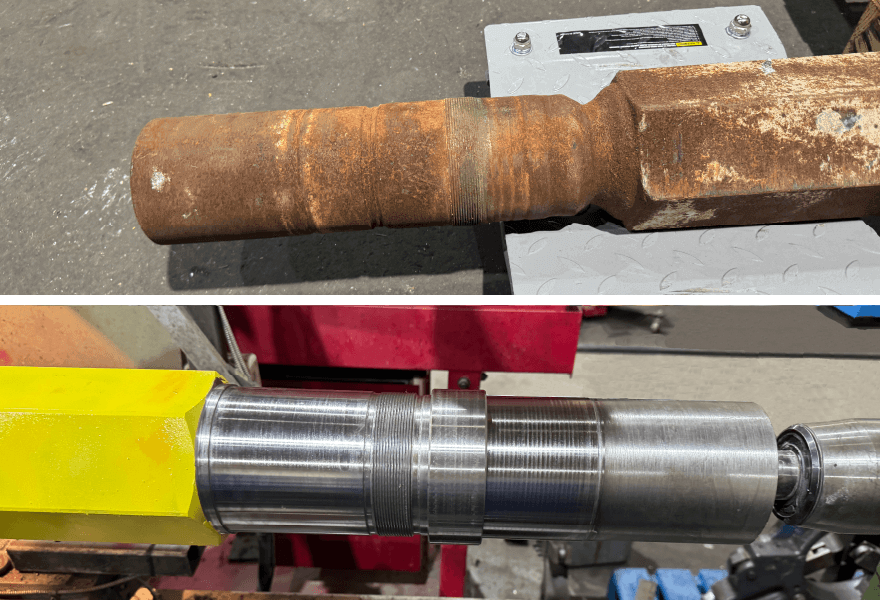

Aggregates case study – Mixer Shaft

Our client was experiencing significant wear in mixer shafts within 18 months of their installation. SpiralWeld designed and delivered a sustainable solution to extend shafts’ operational life, reducing downtime and the need for costly replacements.