The SpiralWeld™ Benefit

Combined Cycle Gas Turbine (CCGT) power plant are a core part of the power generation make up for the UK. SpiralWeld™ has a wealth of experience on CCGT control valve remanufacture and has supported over 60% of the UK CCGT operating installed base with over 100 different component solutions available. Each solution has been developed to address a specific customer need and we are able to draw upon our knowledge and expertise to develop bespoke solutions for your components.

Customer operating data has shown CCGT components that have undergone SpiralWeld™ ReManufacture+ recovery have performed better than standard OEM parts, seeing more than double the starts before any maintenance intervention and extending maintenance intervals to align to standard outage cycles and beyond.

A SpiralWeld™ ReManufactured component will:

- Give you confidence in reliabilty during operation

- Reduce the cost of your replacement parts

- Reduce plant downtime

- Reduce spare inventory

If you have a specific requirement in mind and want to discuss if SpiralWeld™ could be the right solution, then please contact us and the right member of our expert team will get in touch.

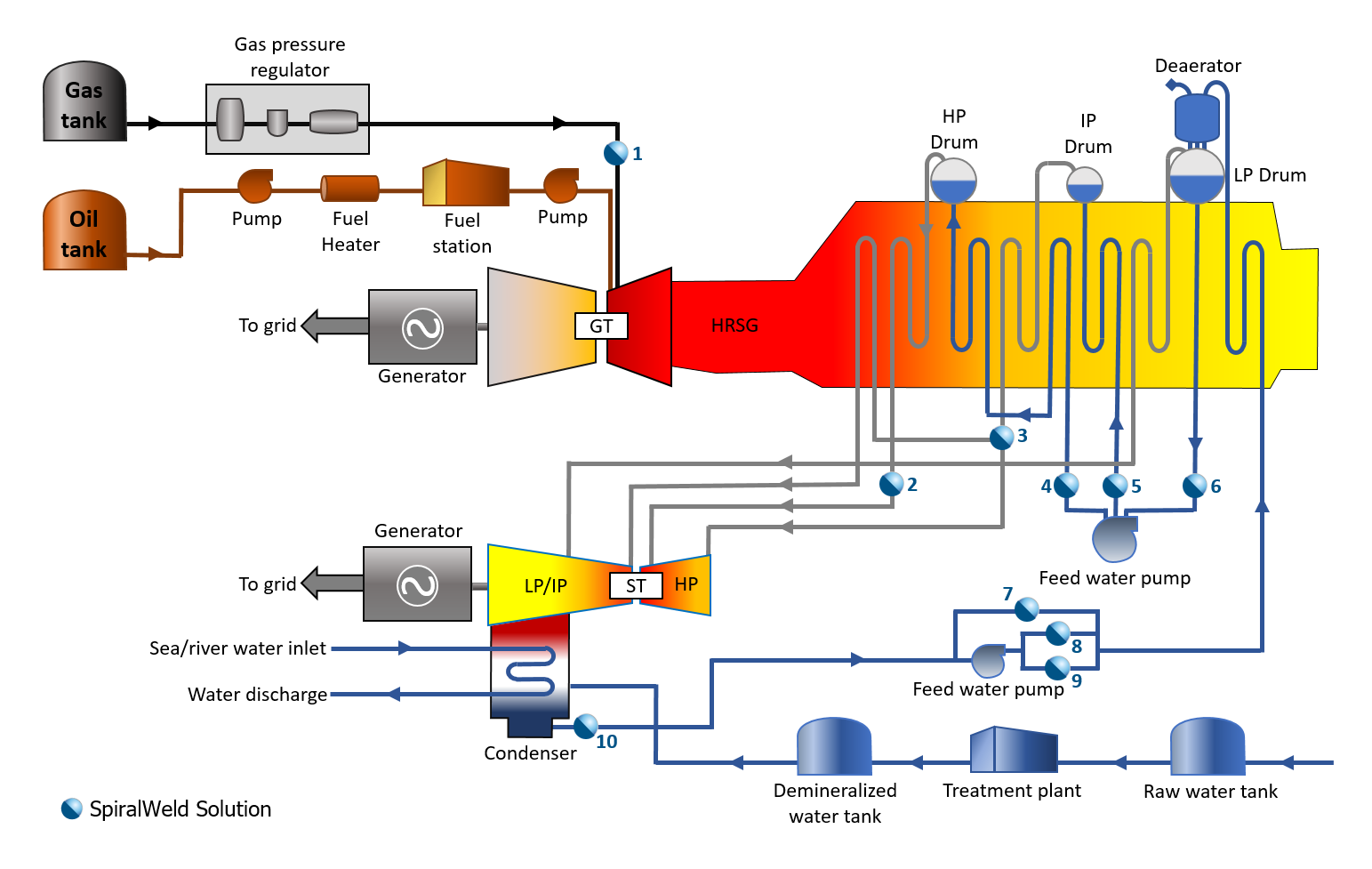

SpiralWeld™ Ltd experience within a typical combined cycle gas turbine system

#1 Fuel Gas Preheater Valve

Purpose

Regulate and control gas pressure and flow through fuel gas preheater system.

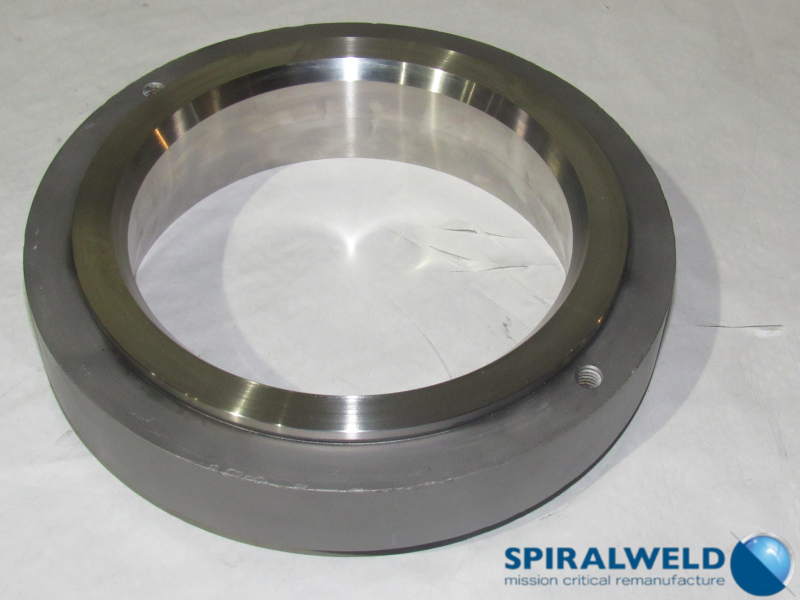

SpiralWeld™ ReManufacture+ Solutions

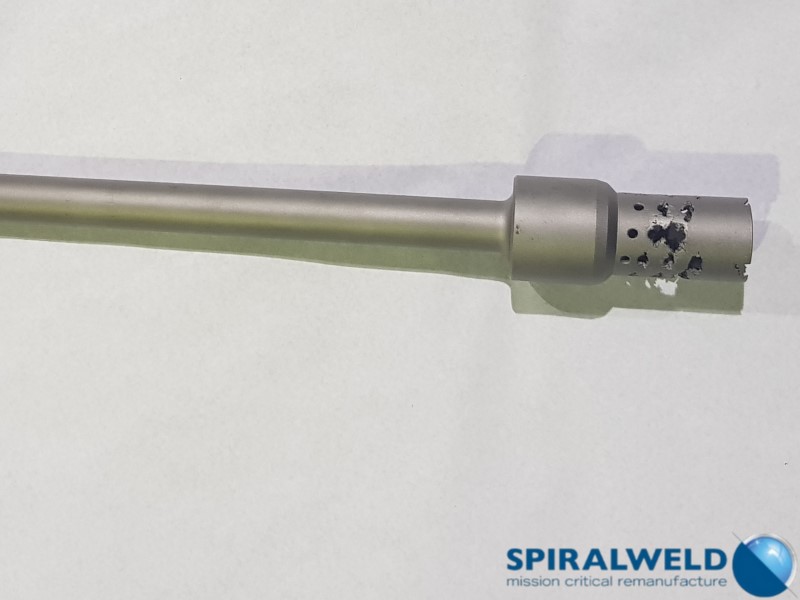

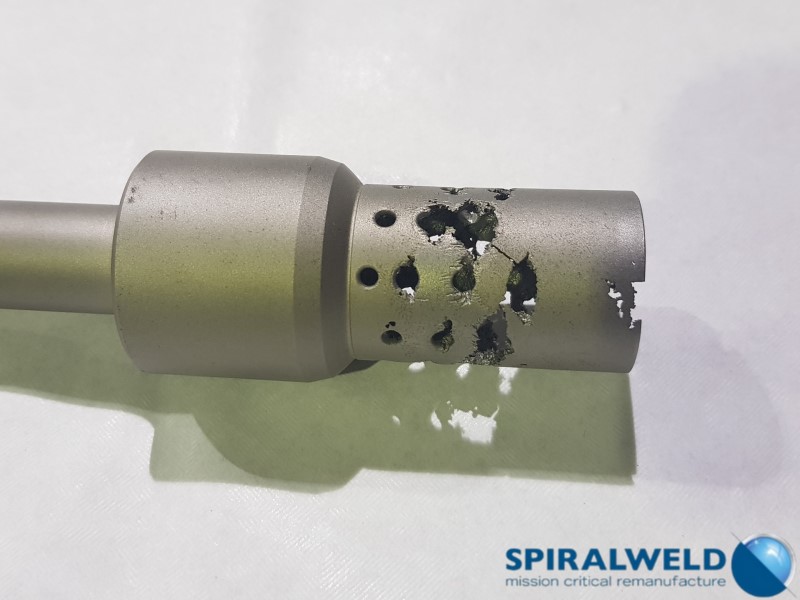

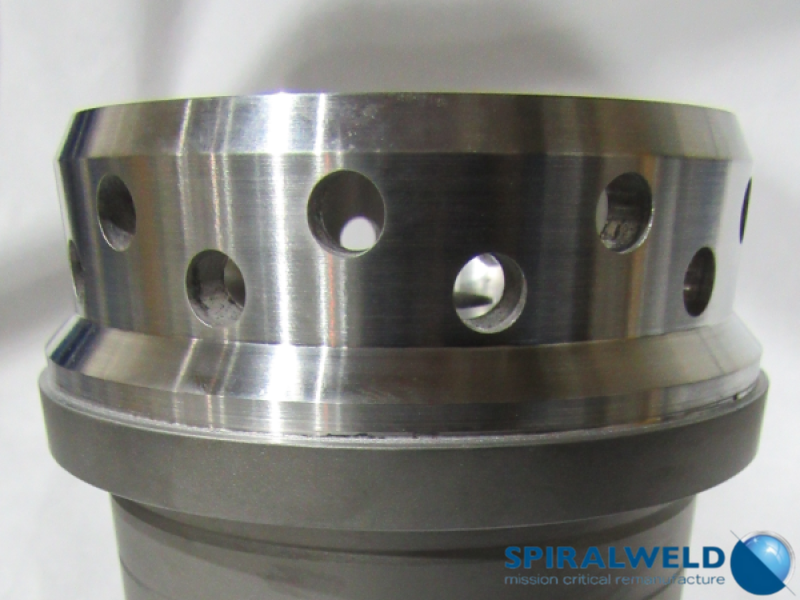

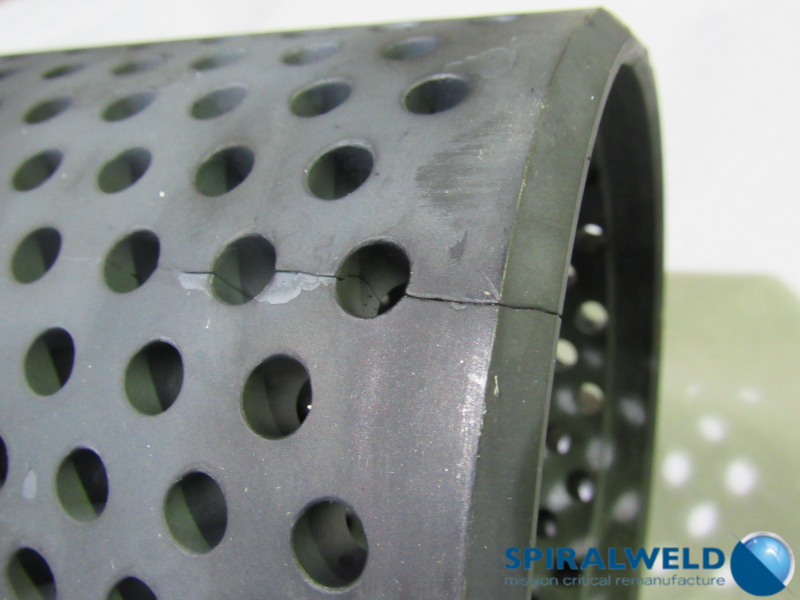

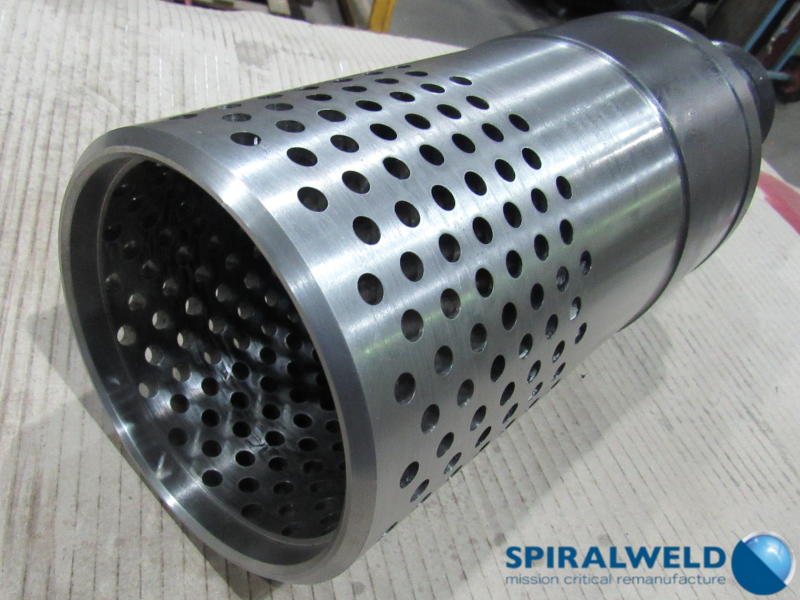

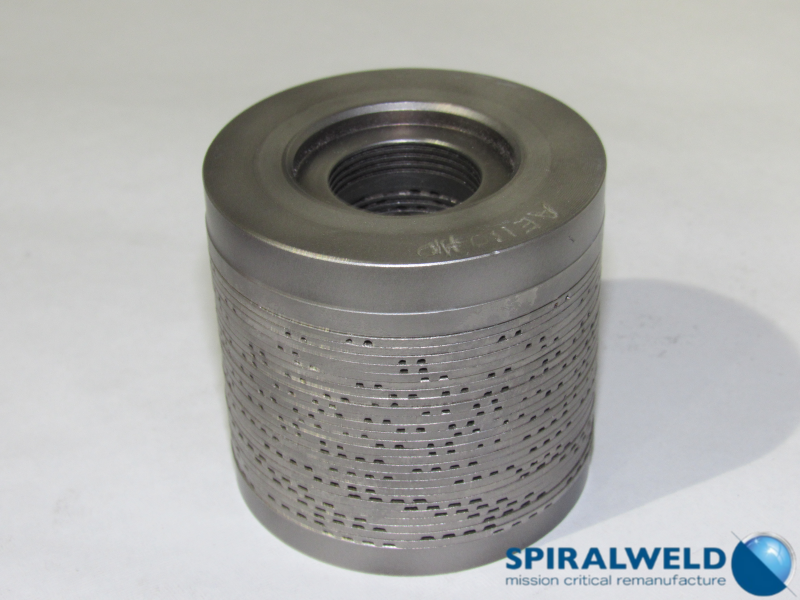

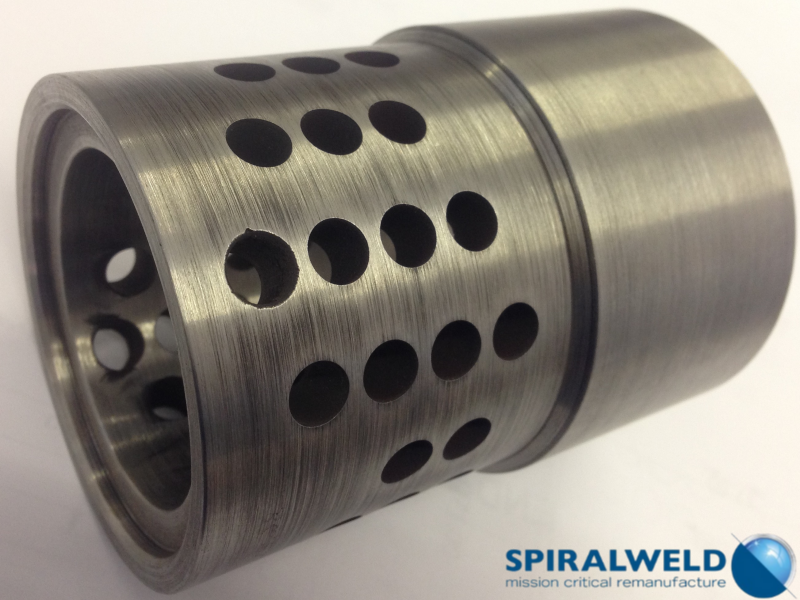

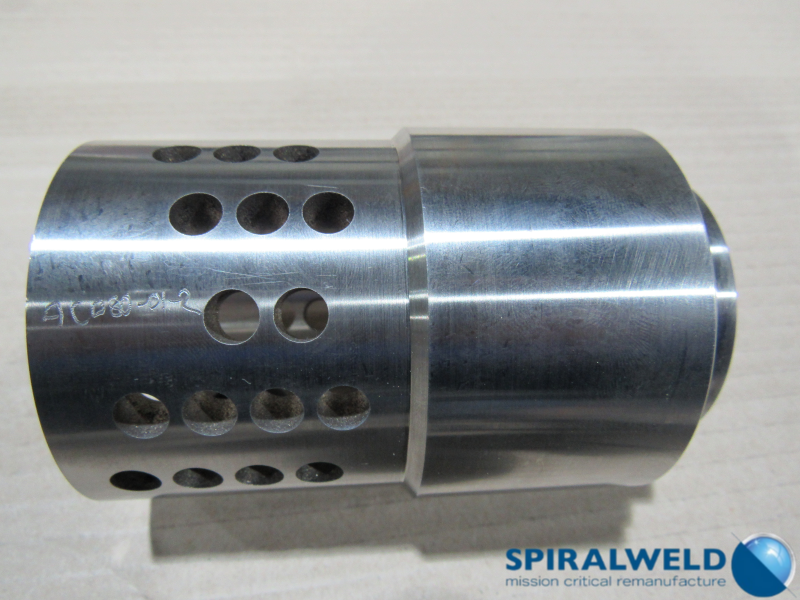

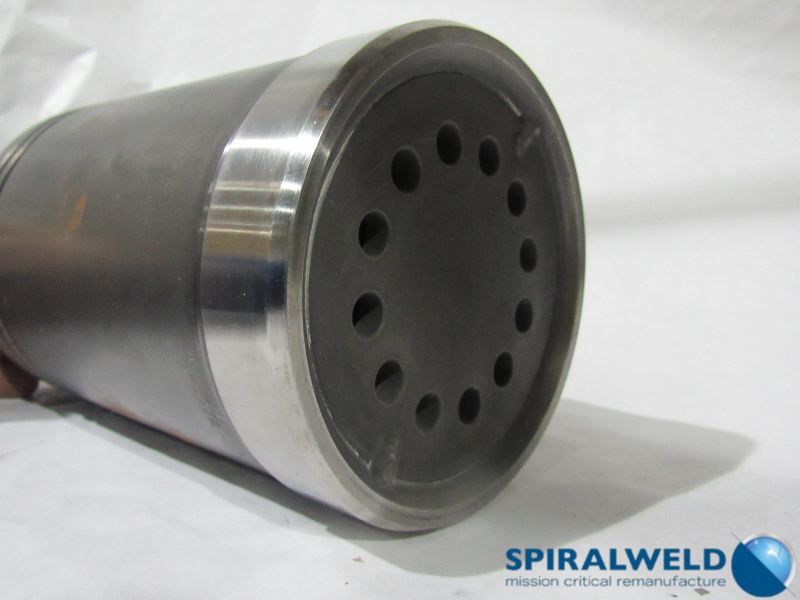

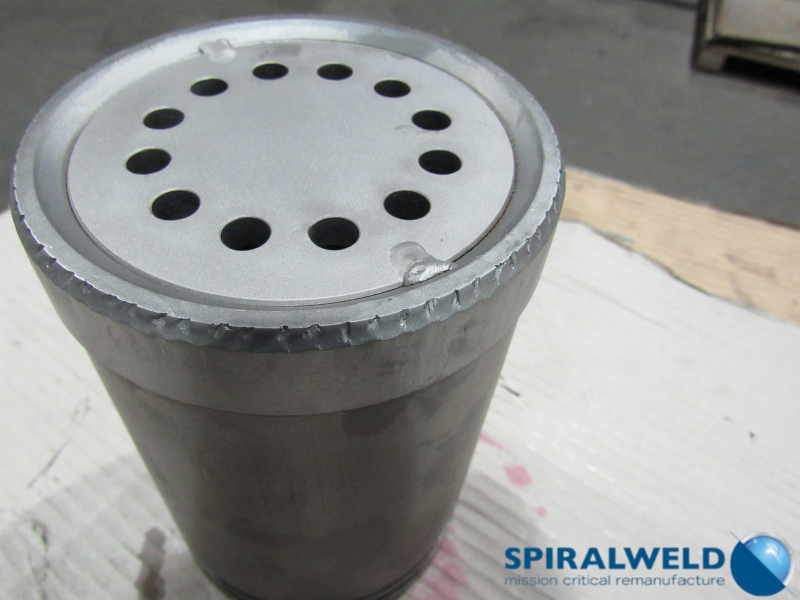

Plug: Perforated skirt and control seat upgrade with our advanced cobalt alloy

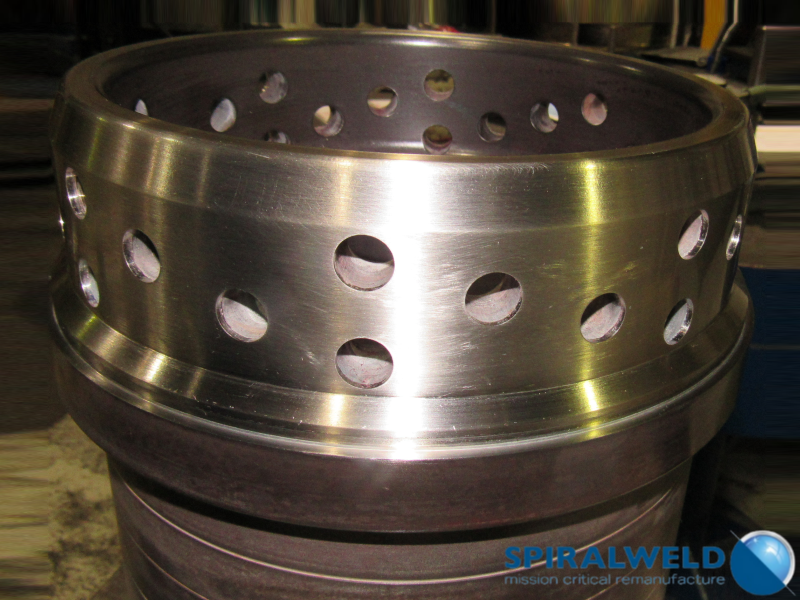

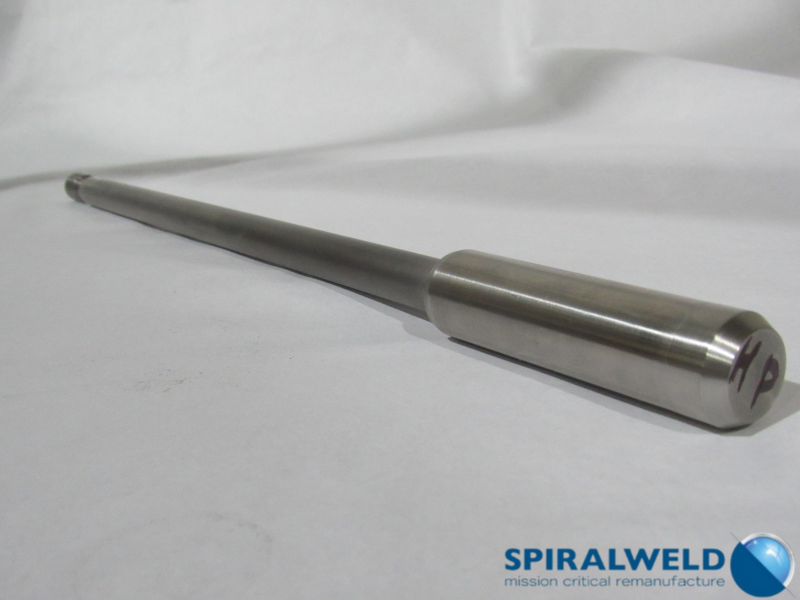

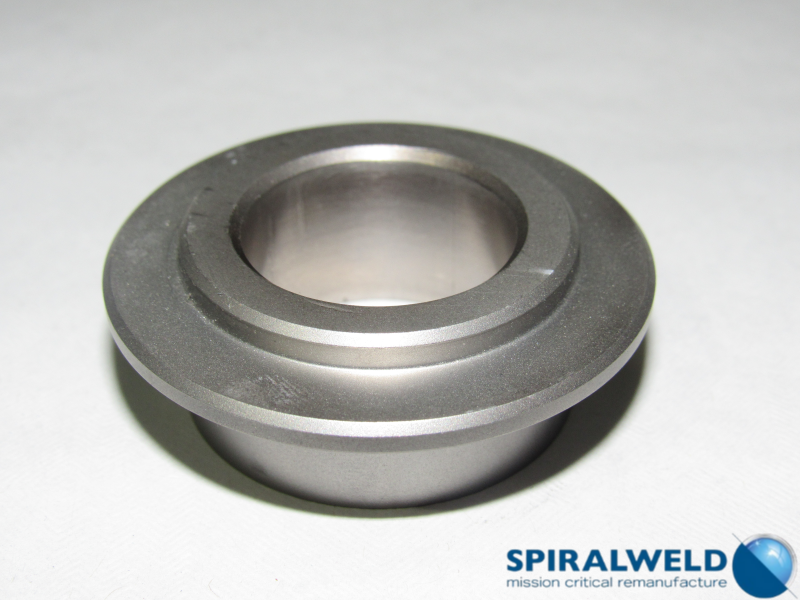

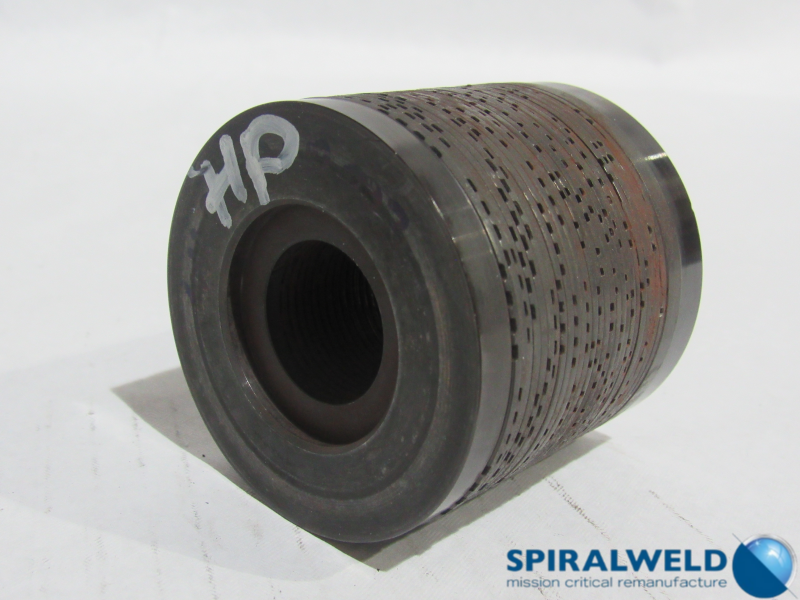

#2 HP Bypass Valves

Purpose

Maintain and control main line HP steam pressure during start up or a trip event, dumping steam to the condenser.

SpiralWeld™ ReManufacture Solutions

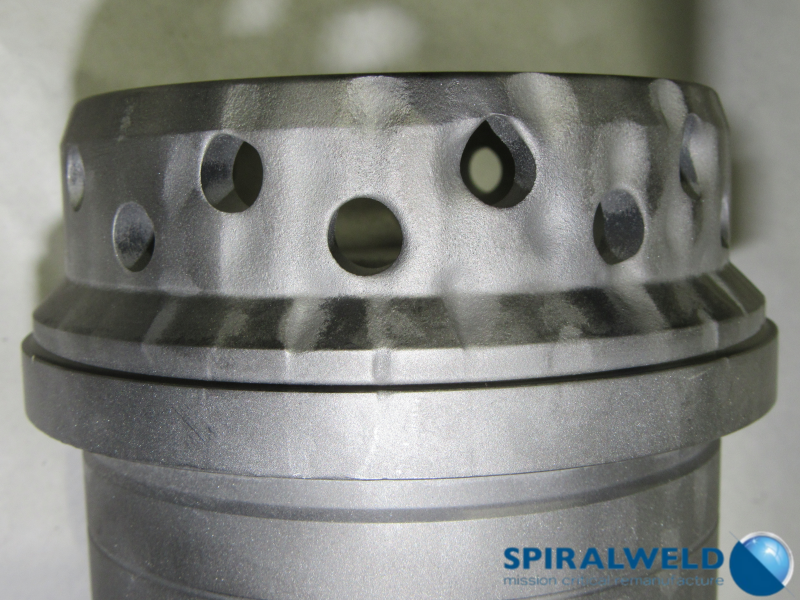

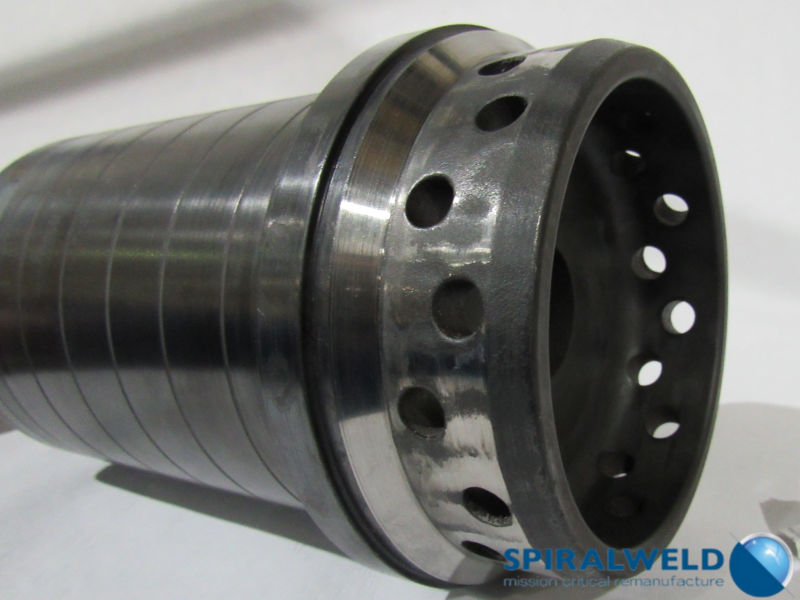

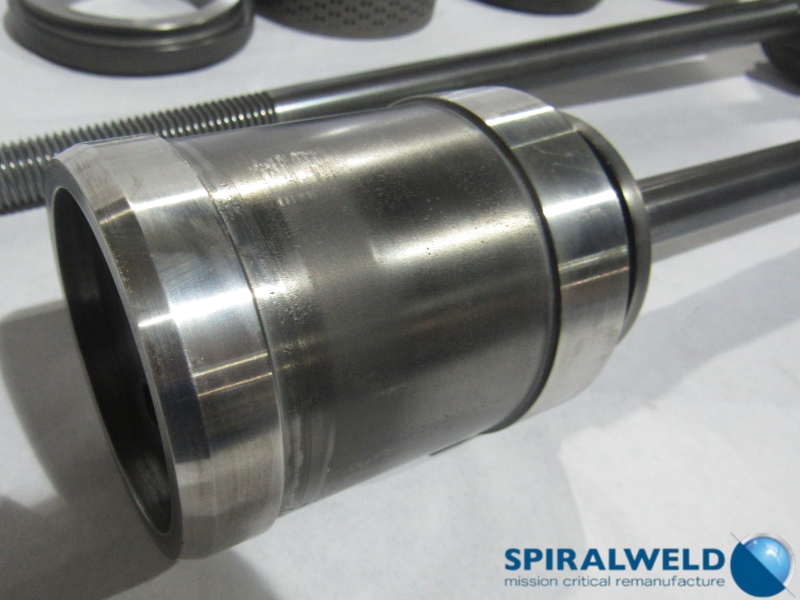

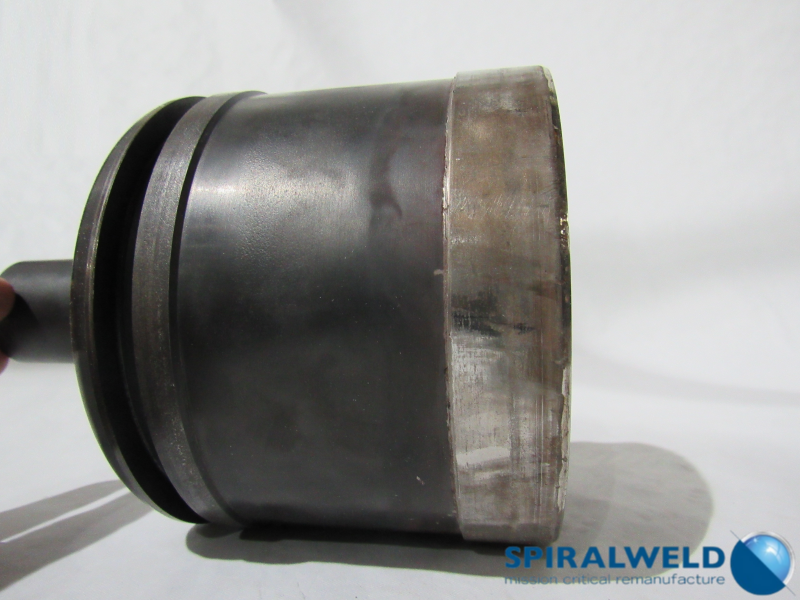

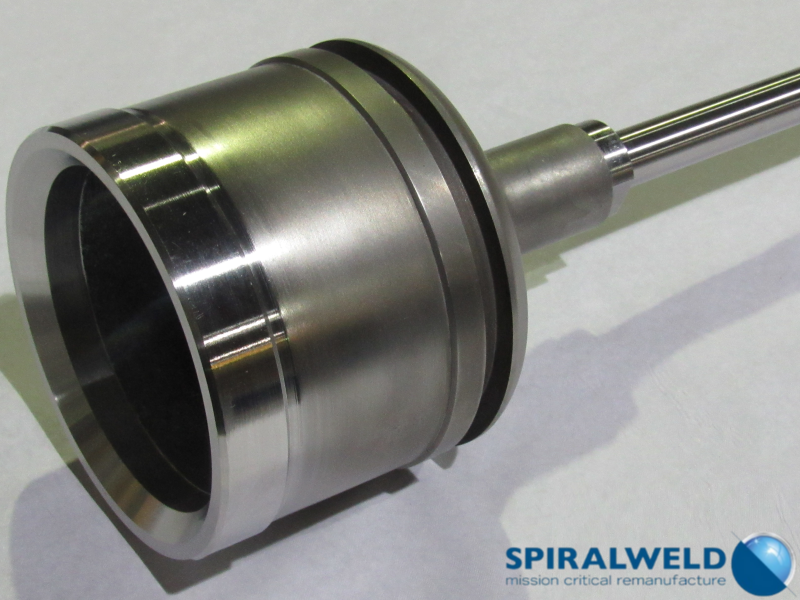

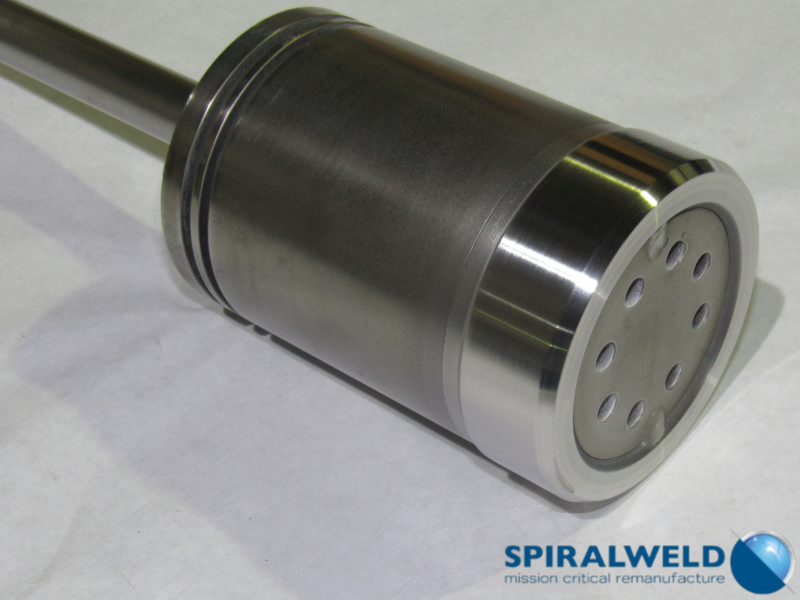

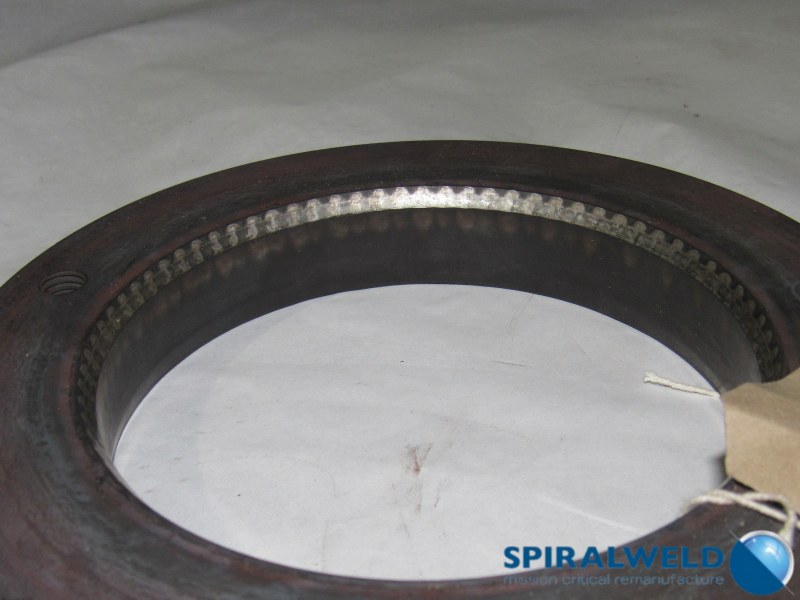

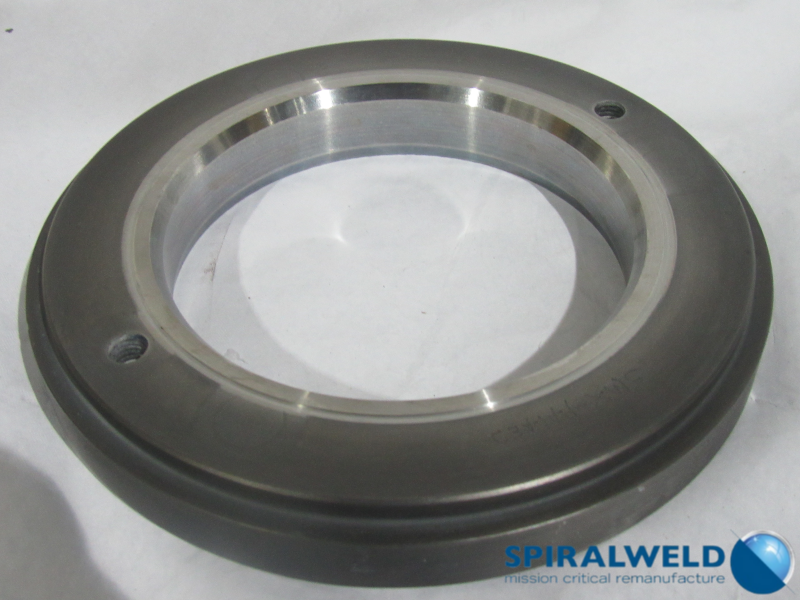

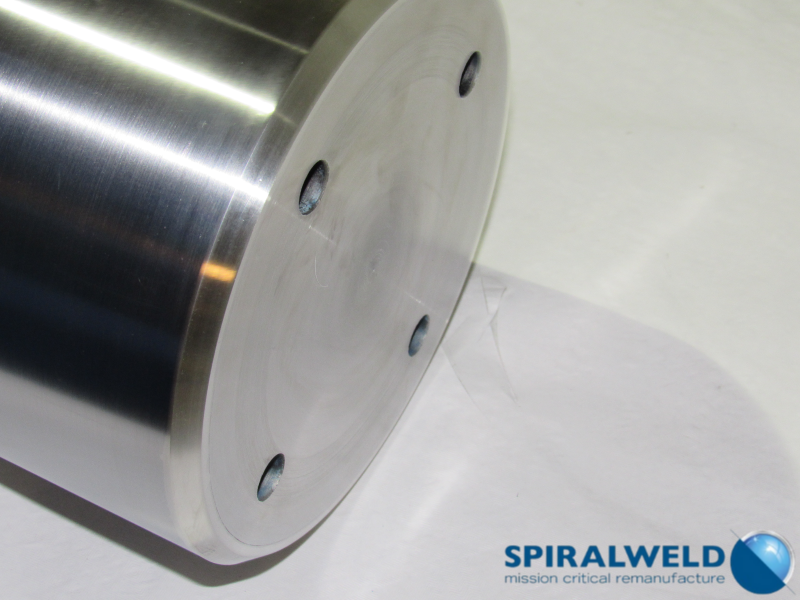

Main plug: control seat, perforated skirt & pilot seat upgrade

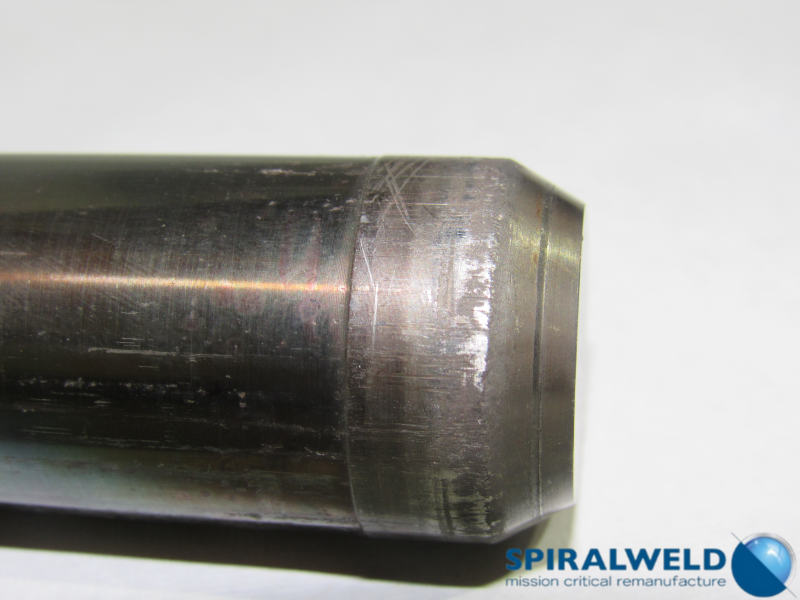

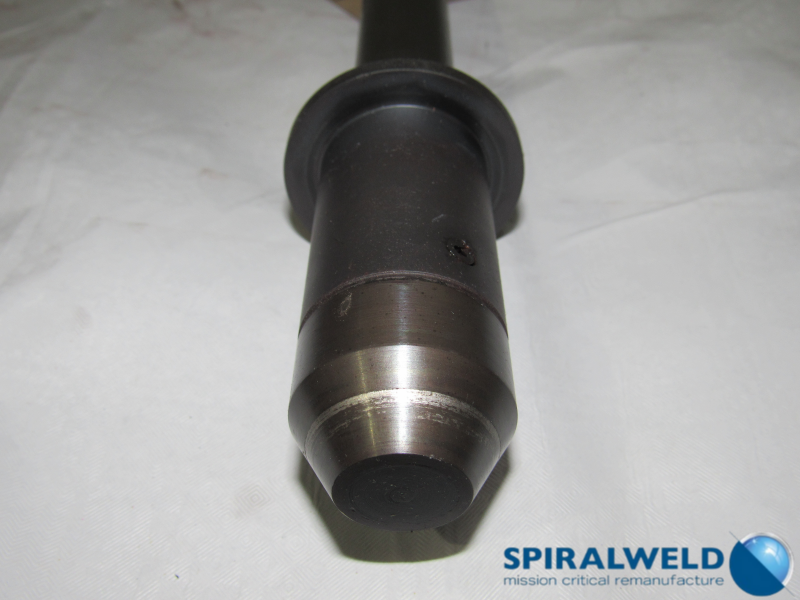

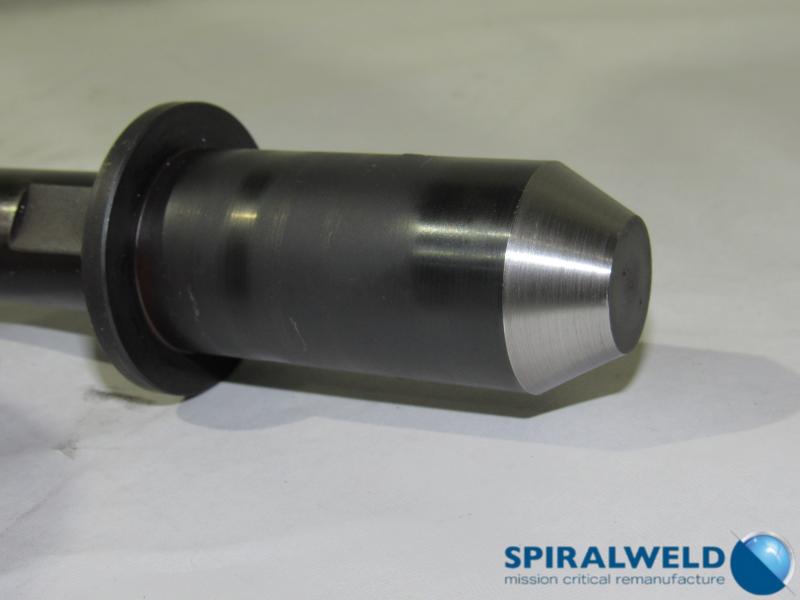

Pilot plug: stem recovery with parent materials, control seat upgrade

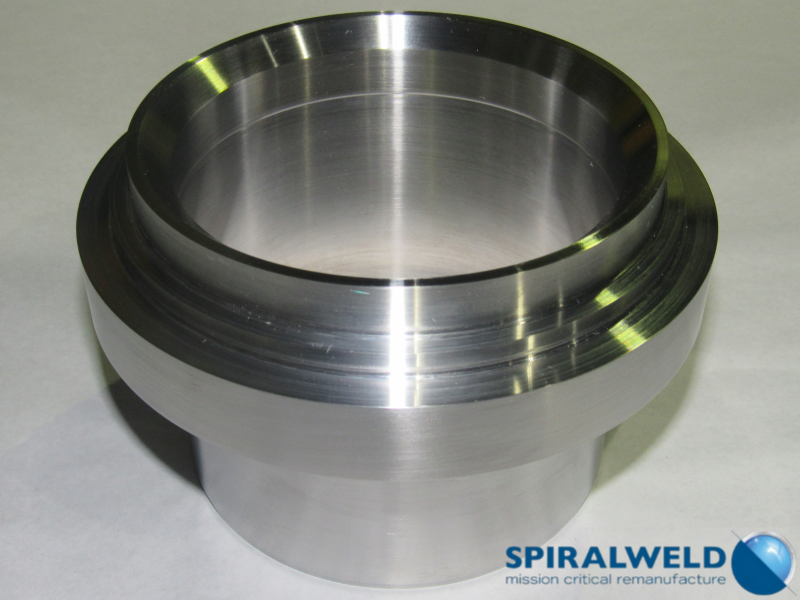

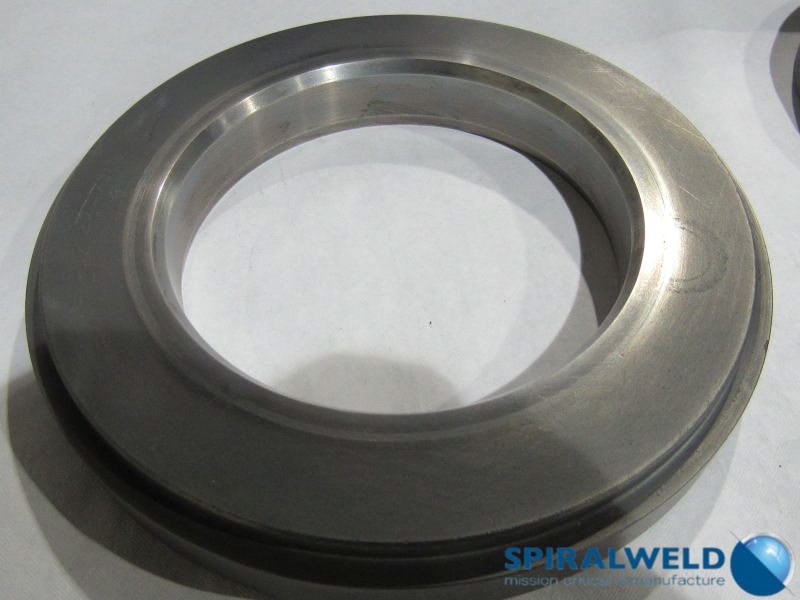

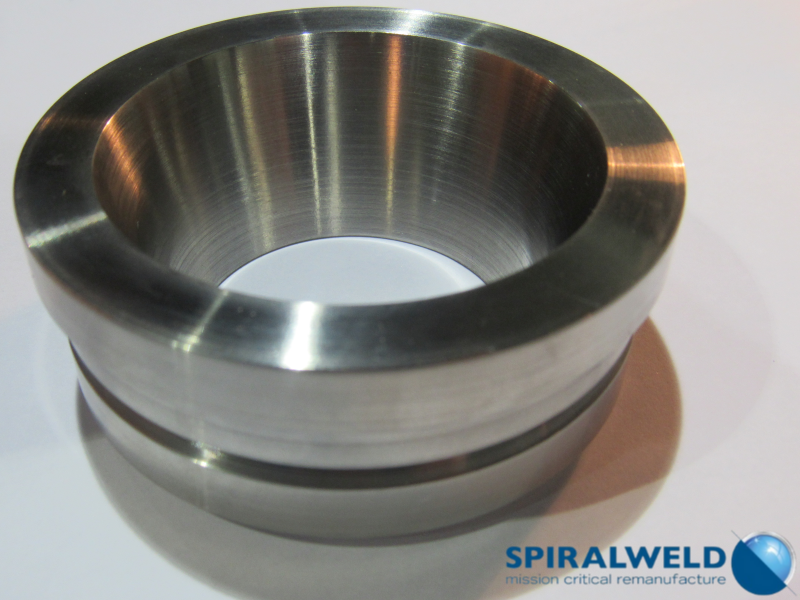

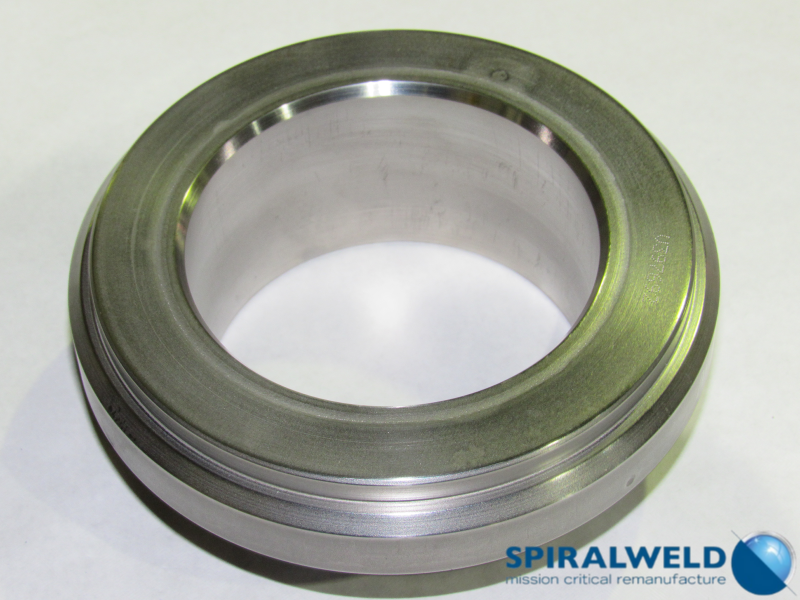

Fixed seat: Manufacture+ and seat upgrade

New component Manufacture+ available should condition be beyond ReManufacture

#3 IP Bypass Valves

Purpose

Maintain and control IP steam pressure to IP turbine stage

SpiralWeld™ ReManufacture+ Solutions

Main plug: control seat, perforated skirt & pilot seat upgrade with our advanced cobalt alloy

Pilot plug: stem recovery with parent materials, control seat upgrade with our advanced cobalt alloy

Fixed seat: seat upgrade with our advanced cobalt alloy

#4 HP Feed Water Regulator

Purpose

Maintain and control feed water flow into HP side of HRSG and steam header

SpiralWeld™ ReManufacture+ Solutions

Plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

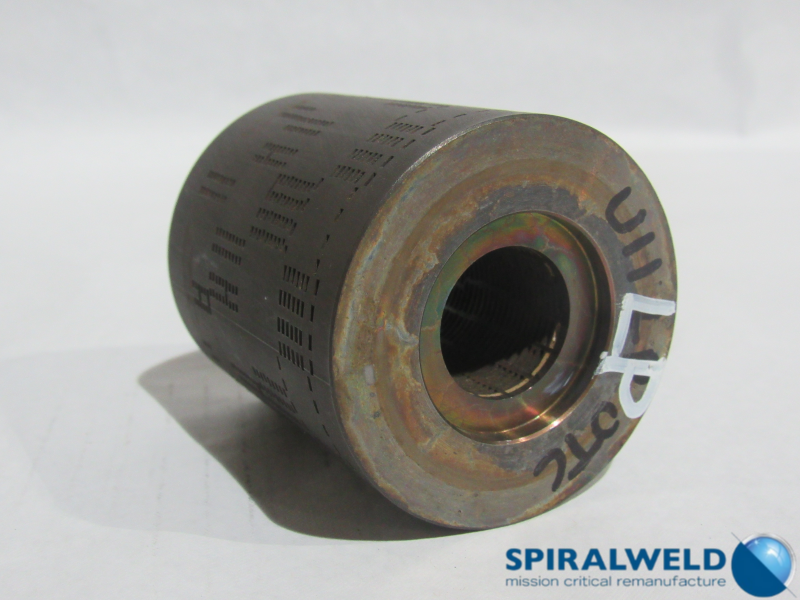

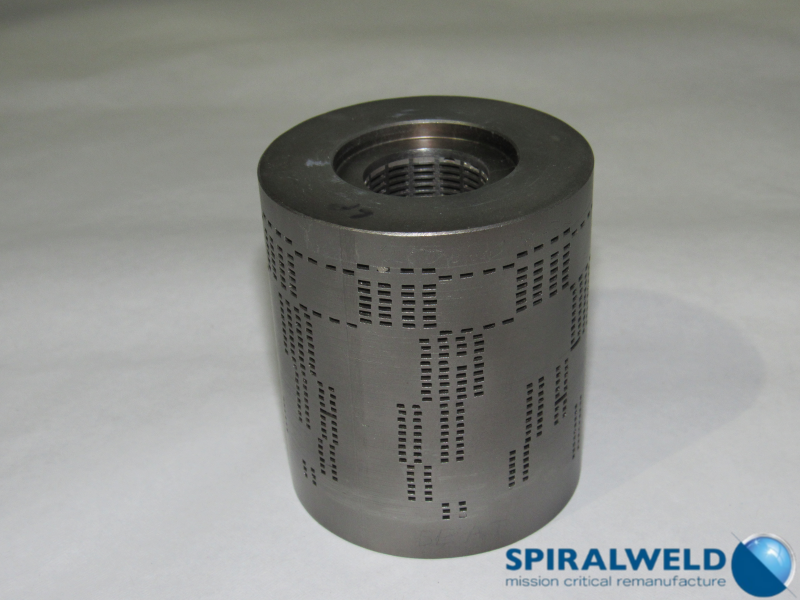

Drag valve: clean and reconstitute labyrinthine stack plates

New component Manufacture+ available should condition be beyond ReManufacture

#5 IP Feed Water Regulator

Purpose

Maintain and control feed water flow into IP side of HRSG and steam header

SpiralWeld™ ReManufacture+ Solutions

Plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

Drag valve: clean and reconstitute labyrinthine stack plates

New component Manufacture+ available should condition be beyond ReManufacture

#6 LP Feed Water Regulator

Purpose

Maintain and control feed water flow into LP side of HRSG and steam header

SpiralWeld™ ReManufacture+ Solutions

Plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

Drag valve: clean and reconstitute labyrinthine stack plates

New component Manufacture+ available should condition be beyond ReManufacture

Other Feed Water Regulator Designs

Purpose

Maintain and control feed water flow into HRSG and steam header

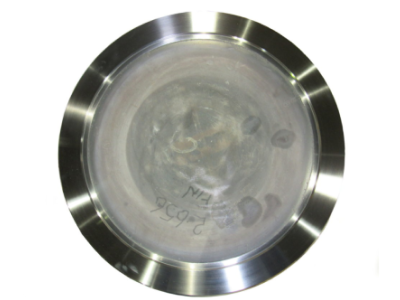

SpiralWeld™ ReManufacture+ Solutions

Plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

Cage trim: bore surface upgrade with our advanced cobalt alloy

New component Manufacture+ available should condition be beyond ReManufacture

#7 Minimum flow valve (Schroedahl type)

Purpose

Maintain and control feed water pressure at low operating flow during startup

SpiralWeld™ ReManufacture+ Solutions

Control head: bore, lever arm/pin, piston upgrade with our advanced cobalt alloy

Vortex bush: seat upgrade with our advanced cobalt alloy

Vortex plug: washer/bush and seat upgrade with our advanced cobalt alloy

Nozzle: upgrade design with our advanced cobalt alloy

Manufacture+ of all parts featuring upgraded control and operating surfaces providing enhanced service life

#8 33% Feed Water Regulator

Purpose

Provide initial feed water flow into HRSG during start up activites

SpiralWeld™ ReManufacture+ Solutions

Main plug: control seat upgrade with our advanced cobalt alloy

Pilot plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

New component Manufacture+ available should condition be beyond ReManufacture

#9 100% Feed Water Regulator

Purpose

Maintain and control feed water flow and pressure into HRSG during full load operation

SpiralWeld™ ReManufacture+ Solutions

Main plug: control seat upgrade with our advanced cobalt alloy

Pilot plug & stem: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

New component Manufacture+ available should condition be beyond ReManufacture

#10 Condensate Discharge

Purpose

Maintain and control return of condensate from condeser back to feed water system

SpiralWeld™ ReManufacture+ Solutions

Main plug: control seat upgrade with our advanced cobalt alloy

Fixed seats: seat upgrade with our advanced cobalt alloy

New component Manufacture+ available should condition be beyond ReManufacture