For 30 years, SpiralWeld has repaired and remanufactured vital components used throughout the water utilities sector, creating parts as good as new or even better! Our utilities clients include water companies and their subcontractors.

Our expert team supports a wide range of key components of differing sizes, including part assemblies. These include:

- Wastewater pumps

- Biofilter columns

- Shredding Impellers

- Crankshafts

- Augers

- Valves

- Waste Drum Filters

- Macerators

- Air compressors

- Fans

Benefits of using SpiralWeld

- Cost savings of up to 80% compared to buying new from the OEM

- Much shorter turnarounds, avoiding long lead times for replacement parts

- Extended lifetime for parts considered obsolete or beyond viable repair

Our Services

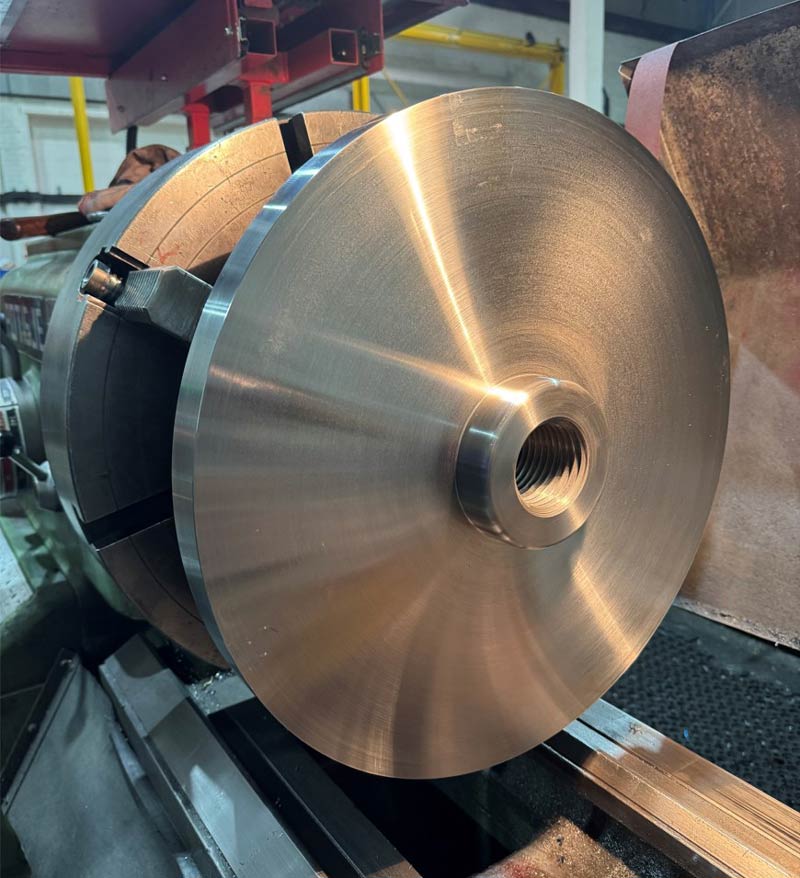

Remanufacture

We take the OEM solution and remake it. The part is returned to full working condition with a service life at least equal to a new part.

Remanufacture+

We take the OEM solution and repair it to better than new! We remanufacture the part using a superior material with properties to suit the service conditions.

A detailed quality plan, certification and warranty can be provided for each project.

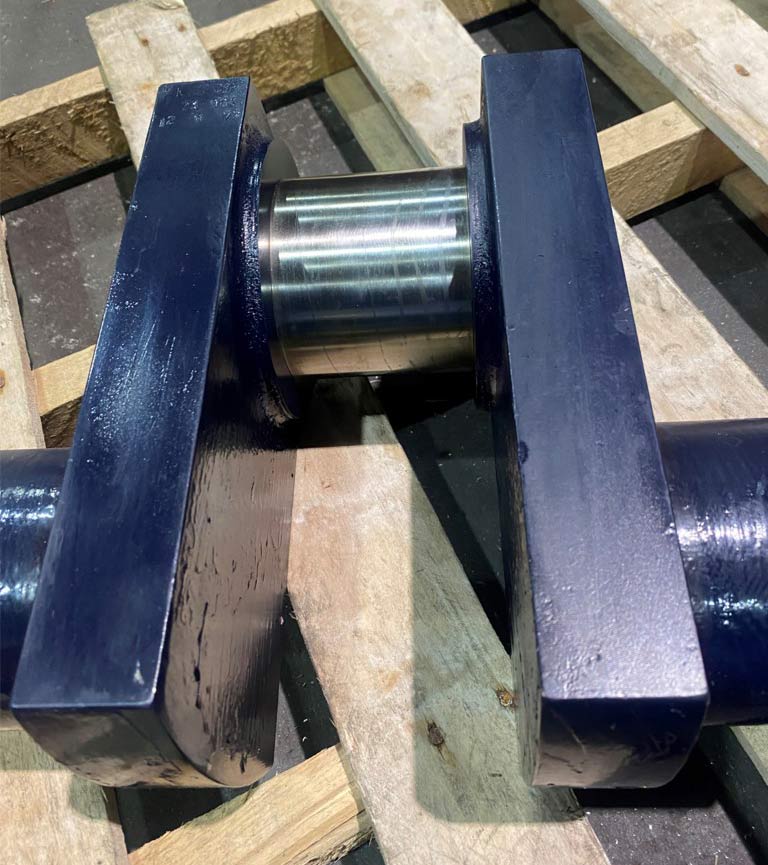

Water utilities case study – Biofilter Column

When a sewage treatment plant biofilter column stopped rotating, SpiralWeld provided a robust solution where other suppliers had failed, with the team working out of hours to ensure the fastest-possible turnaround.

Client response:

“A massive thanks for the Biofilter project – install went exactly to plan and is now fully operational. I’ve certainly had some sleepless nights over it after finding the mess of the previous repairs and some of the setbacks we’ve had!”